Polyethylene potable water mains with an assumed minimum design life of 50 years have been in widespread use in the water industry for more than 30 years.

In the 1980s and 1990s Severn Trent Water in the UK buried two polyethylene pipe test beds in the Midlands. These two test beds near the pumping stations at Great Gates and Coopers Green, had all the pipe material analysed chemically and mechanically before installation. This was documented in several studies as well as the subsequent exhumations in the following years.

So Electrofusion.. it’s a mix of electricity and fusion but what does that mean?

Electrofusion, or EF for short, is a method of joining PE pipe in situations where butt fusion is not practicable, like where valves, elbows and tees need to be added.

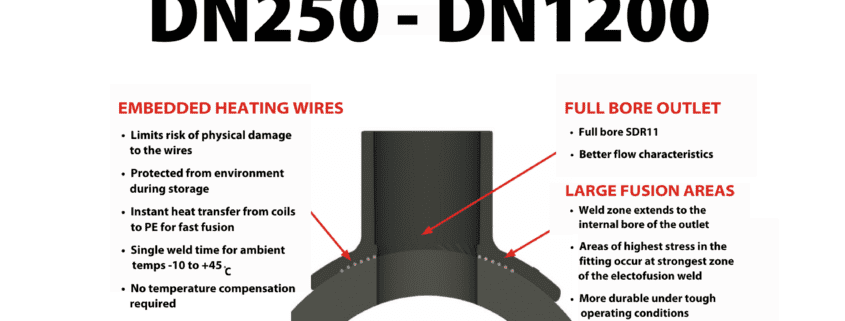

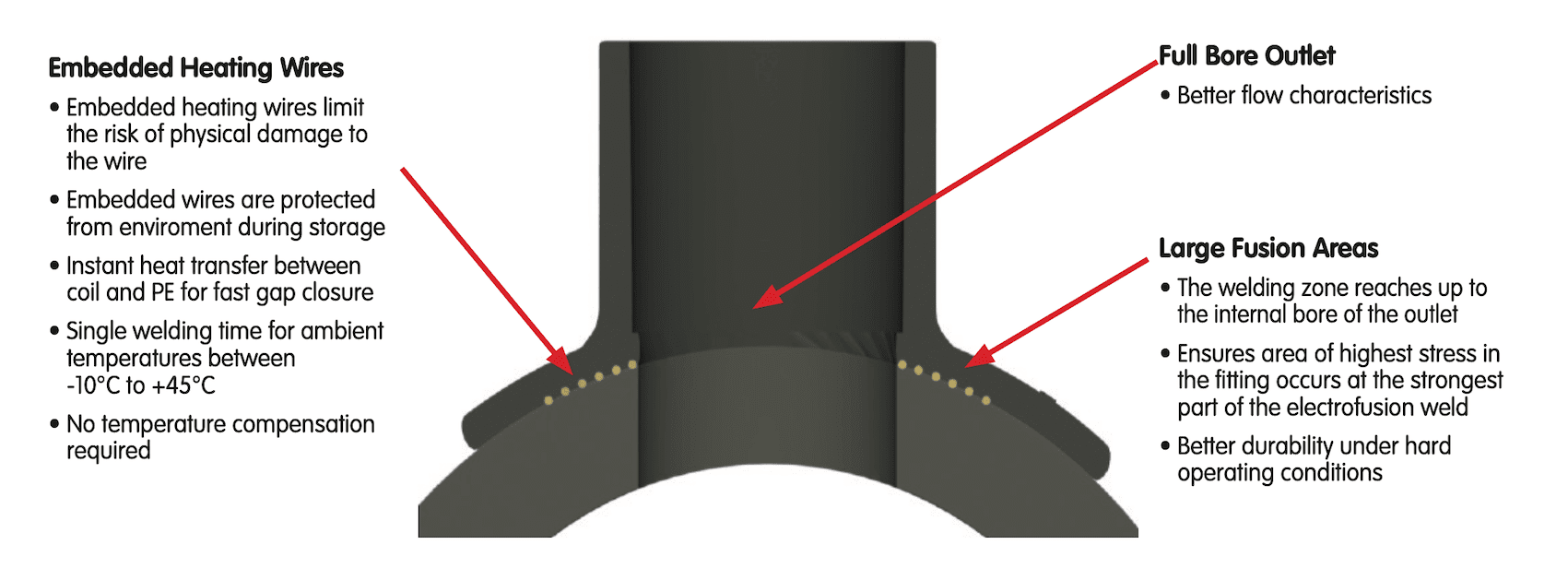

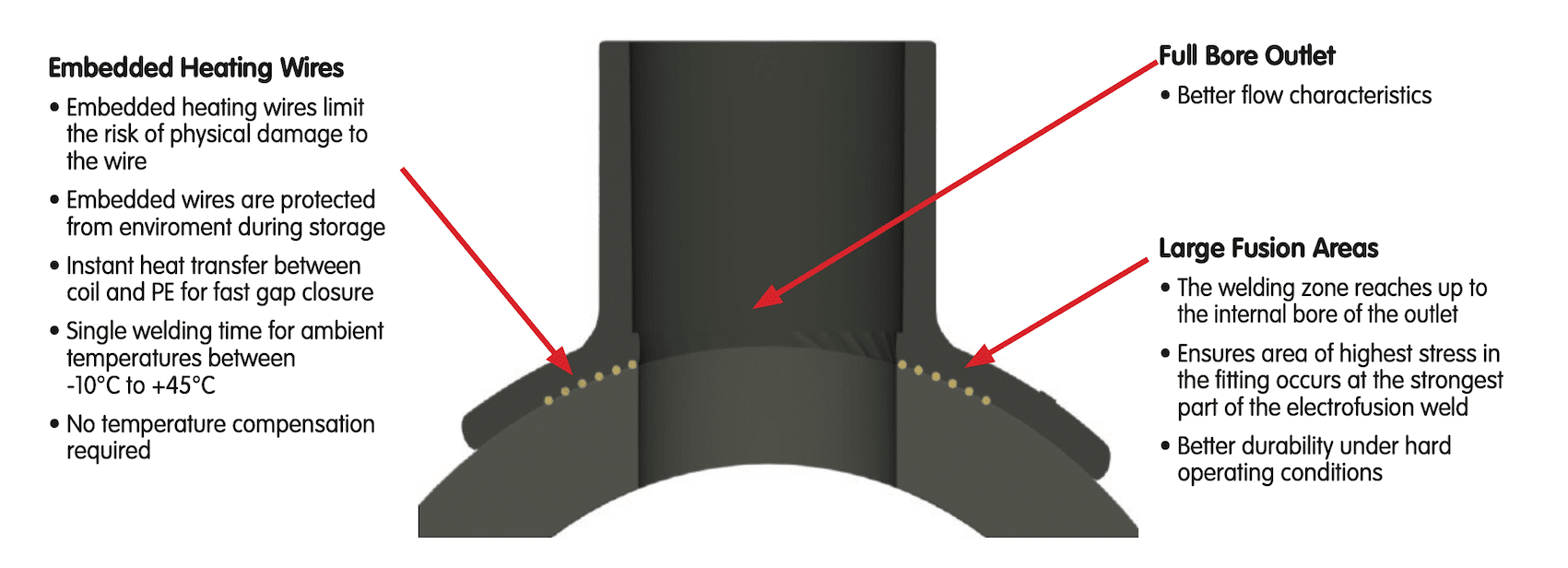

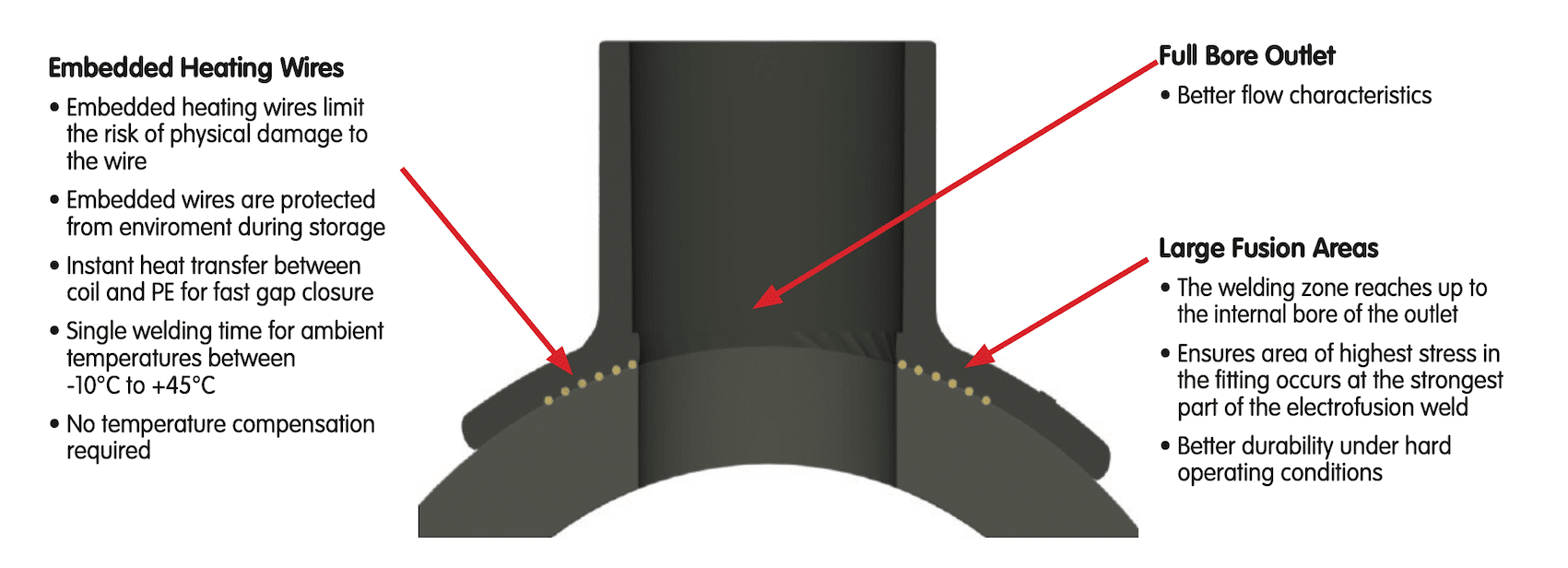

Specialised electrofusion fittings have electrical heating coils imbedded into them. When current is applied to these EF fittings, heat is created which melts the plastic of both the fitting and the pipe.

The plastic from both are forced to mix together under pressure due to the design of the fitting. Once the mixed plastic cools, the pipe and fitting are fused together permanently.

How does EF welding work?

The parameters of each fitting, like the fusion time, are recorded in the barcode on each fitting. These details are entered into the welding control box via a barcode scanner or some control boxes automatically detect a fitting’s settings when it is connected to the machine’s leads.

An electrofusion control box sends electrical current through metal coils inside the fitting. The current causes the metal to heat up. The plastic around the coils begins to melt and forms an expanding pool of hot, molten plastic. The melt pool from the fitting comes into contact with the surface of the pipe. The continued application of current causes the pipe surface to also melt.

The pipe melt and fitting melt is forced to mix as pressure builds up in the coupler area, due to the design of the fitting, forcing the two plastics together. This is key to producing a good weld. Following the end of the weld cycle, the fitting and the pipe are left to cool and the melted material solidifies to form a permanent joint.

Hot and cold zones, sometimes called melt and freeze zones, are formed when the wire coils heat up. The length of these zones is key to achieving melt pressure. The precise positioning of the coils in the fitting is also important to ensure uniform heat distribution.

Fusion parameters: temperature, pressure and time, are controlled by the electrofusion control box and it is fed parameters from the barcode on each fitting, or from the fitting itself. The electrofusion control box also records a report of the procedure with all the settings and data from the weld.

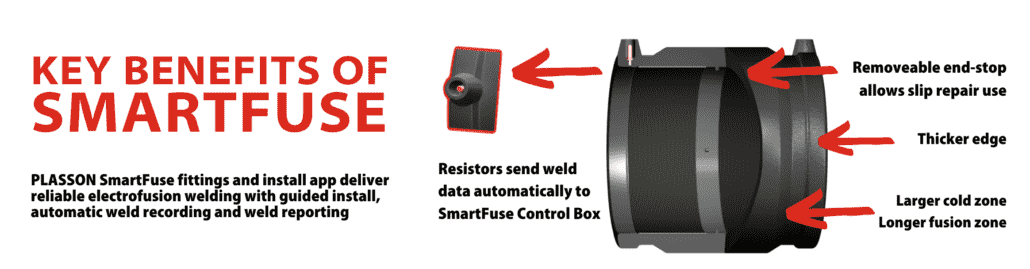

PLASSON has developed the SmartFuse system, which includes specialist fittings, a range of EF weld control boxes and an mobile phone app which guides installation, to help simplify the whole electrofusion process. Using the SmartFuse system makes welding quicker and easier. The automated process helps reduce errors and prompts installers to complete and double check all steps.

You can read more about SmartFuse and watch our demonstration videos here…

PLASSON’s unique design delivers maximum flexibility including offering reliable, leak-free way to connect a number of pipe materials.

Any standard PLASSON fitting can easily adapt to connect several different pipe materials, pipe sizes and also be used as a threaded connection with the help of our handy range of conversion kits.

SmartFuse might just look like a product name etched into PLASSON fittings but it represents our commitment to high quality, reliable electrofusion welding – for installers, asset owners and those who rely on what comes down the pipes.

Over the last 50 years, metallic pipelines have been increasingly replaced by thermoplastic systems such as polyethylene, or PE. This is due to the significant advantages of PE like environmental resistance, especially corrosion, low maintenance demands and ease of installation; PE pipelines can even endure earthquakes.

Most newly installed water, sewage and gas distribution pipelines will be PE pipelines and they are increasingly being joined by electrofusion or EF. Electrofusion is considered the most reliable method of joining gas-carrying pipes. In fact, the gas industry was where EF was first used since gases can be hazardous if not secured properly.

THE KEY TO RELIABLE LONG-LASTING INFRASTRUCTURE

Given the obvious need for reliable, long-lasting infrastructure, developing high quality electrofusion fittings and systems for installation has been a PLASSON priority.

With specialized control boxes, reliable electrofusion fittings and precision tooling, PLASSON’S electrofusion range helps deliver better electrofusion welding.

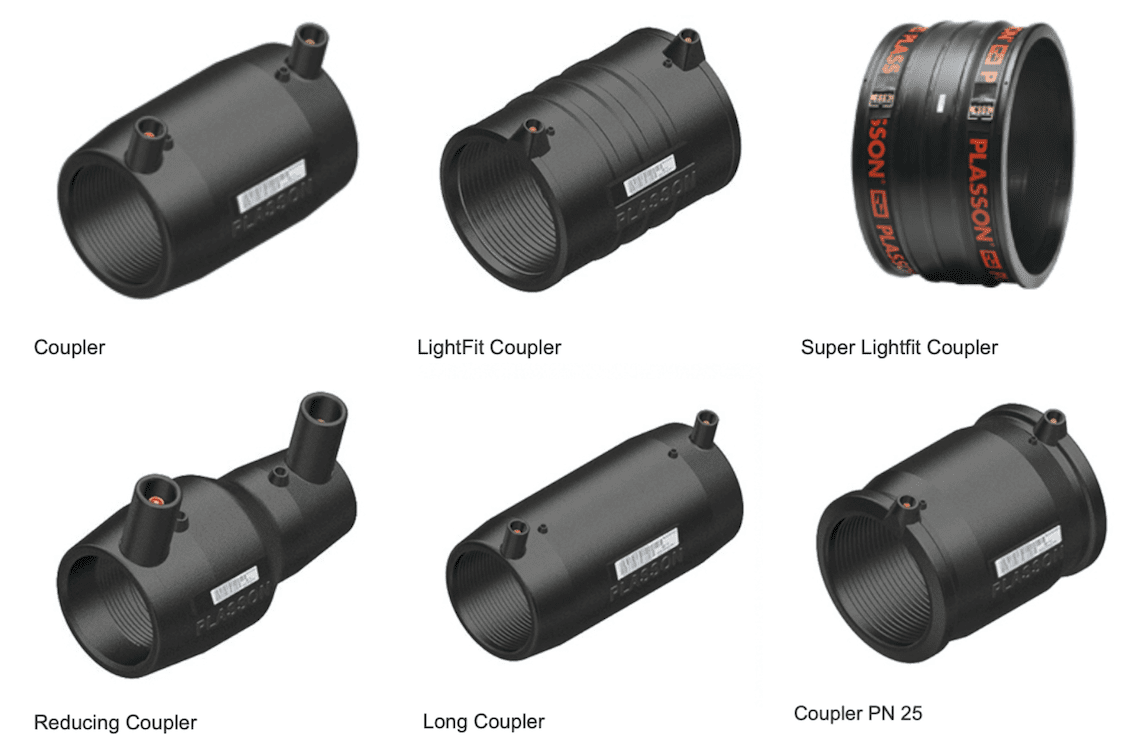

PLASSON electrofusion fittings range from options for small diameter poly pipe, like 16mm and 20mm, to options for large diameter civil water and waste water pipes at 400mm to 800mm, 900mm and even 1000mm.

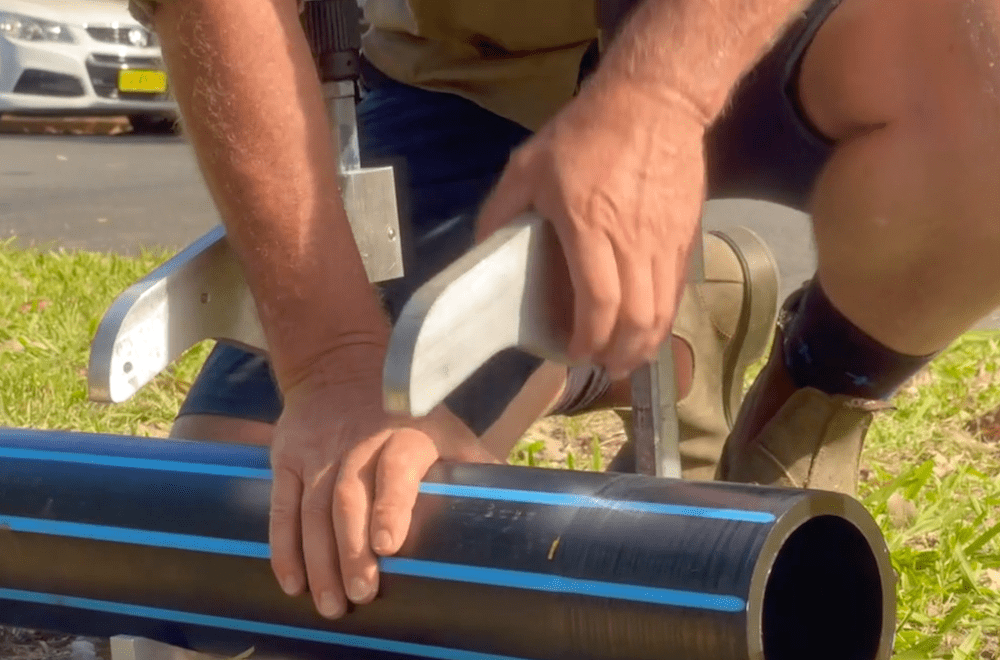

Electrofusion delivers reliable results on small and large diameter poly pipe. EF is also suitable for pipes with a small diameter since it does not shrink the inner diameter of the pipe. So whether welding a 32mm to 1/2″ brass transition fitting or a saddle onto 63mm blue stripe pipe, PLASSON electrofusion fittings are engineered to deliver quality electrofusion welds.

TECHNOLOGY THAT WORKS FOR YOU

The SmartFuse system offers fully automated welding and, when paired with the SmartFuse app, delivers image capture and cloud storage for all weld records. With the click of a button, weld data is stored and accessible, anywhere, anytime.

The SmartFuse app helps lower operational costs, reduces mistakes and joins can be easily traced and identified via the GPS data that is part of every SmartFuse weld record.

PLASSON is committed to innovation in the EF field. As a future focused company, we are continually working to improve what we offer, to facilitate better electrofusion welding, deliver enhanced asset management and asset visibility.

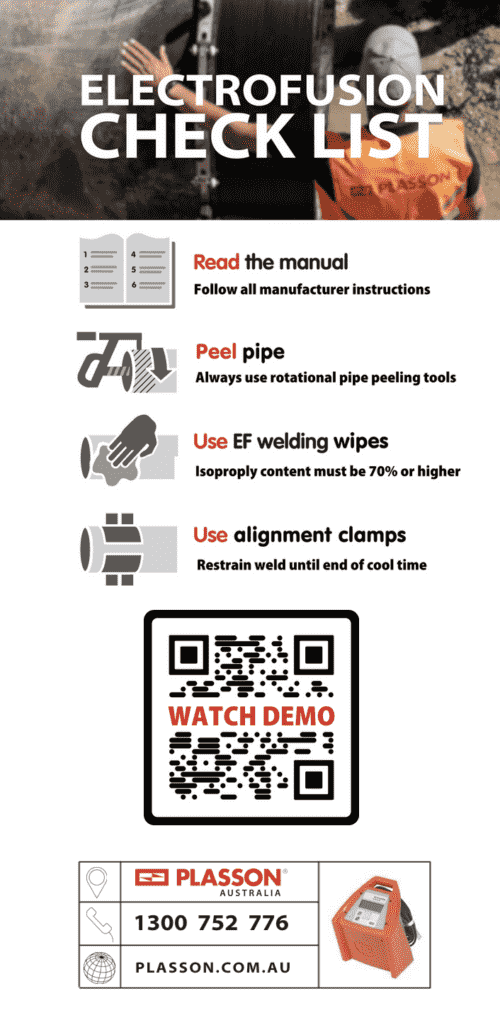

TIPS TO SIMPLIFY EF WELDING

Are you searching for electrofusion welding tips? Looking for that magic piece of advice wrapped up in an easy to watch video? Achieving good electrofusion welds is not quite that simple but you have come to the right place!

The best tip to achieving good EF welds is summed up in two simple words: “precision” and “accuracy”. Whether you are installing a 16mm coupler or a 1000mm fitting, precision and accuracy is crucial at every step of the process. A good weld is about following all the recommended steps, having the right precise tools to do the job and taking the time to use them accurately.

It may sound simple but quality electrofusion welds are literally built on precision (being exact) AND accuracy (being correct).

“Precision” is about instruments and their parameters.

As an example, vernier calipers will measure precise peel depth during pipe prep down to 0.02 mm. A metal rule is precise to 1 mm. That makes it perfect for witness marks but rules (!) it out for gauging precise peel depth.

Here is where “accuracy” steps in – the correct tool used correctly.

PIPA – the Plastics Industry Pipe Association of Australia – has created electrofusion industry guidelines, called POP001. It outlines the precison tools, accurate measurements and correct procedures (Best Practice) for EF welding.

Following the Best Practice steps in POP001 is the by far the best tip for achieving quality electrofusion welds.

Click here to read or download a copy… It has plenty of easy to understand diagrams and documents all the steps and measurements you need for successful electrofusion.

PLASSON created the SmartFuse EF system to deliver a framework to support the precision and accuracy required for successful electrofusion welding.

This system includes SmartFuse fittings with accurate welding parameters preloaded, robust welding control boxes which automatically detect weld parameters for all SmartFuse fittings and a free mobile app to guide installation and record key details, like GPS location, fitting type and barcode, for easy downstream management.

SmartFuse fittings have in-built resistors that feed accurate weld parameters to the SmartFuse control box once the fitting is connected. No manual entry and no scanning means it is not only faster to set up each and every weld but the potential for inaccurate input errors is eliminated.

The SmartFuse mobile app also helps make welding more accurate and precise. When using the app, installers are guided through weld steps, prompted to double-check settings and asked to confirm and record with photos of each step.

All visual records are stored along with details of the fitting being installed, precise location, installer ID, control box weld data and even the temperature on the day!

Weld data can be saved on site via USB, which is handy in remote areas with limited internet access, or, if you are using the SmartFuse App, data can be automatically uploaded to the cloud.

This gives managers and asset owners a real-time comprehensive picture of what is happening on any job, anywhere, anytime

QUICKER AND SMARTER WELDING

Weld times for PLASSON fittings are specific to the type of fitting. This is automatically detected by the SmartFuse control box. By combining all the elements in the SmartFuse system – the fittings, weld control box and SmartFuse App – users benefit from automatically loading of correct settings and recording of all weld activity.

On top of this, the safe storage of records is also take care as with the SmartFuse App all data can be automatically uploaded to the cloud to your preferred storage provider. Click here to find out how to sign up for a free SmartFuse App account..

The use of the SmartFuse system does not remove the requirement for EF installers to be certified. SmartFuse is designed to support certified electrofusion installers to work efficiently and accurately as well as helping by automatically recording detailed weld data for future reference.

See how SmartFuse fittings and welding control boxes work in this handy demo video:

How PLASSON compression fittings work is a bit of a yarn that starts way back in 1896. Unless you are a trivia junkie, it will probably come as news that one of the most critical precision mechanical components ever developed was patented on May 12, 1896. That was when a Swedish patent for the O-ring was awarded to J.O. Lundberg. Niels A. Christensen was granted a US patent for his O-ring design in 1937.

Like all good ideas, it came to the attention of some pretty big players. The O-ring quickly became the standard seal for hydraulics in the military. The top brass set out the standard sizes and basic design guidelines that remain in use today.

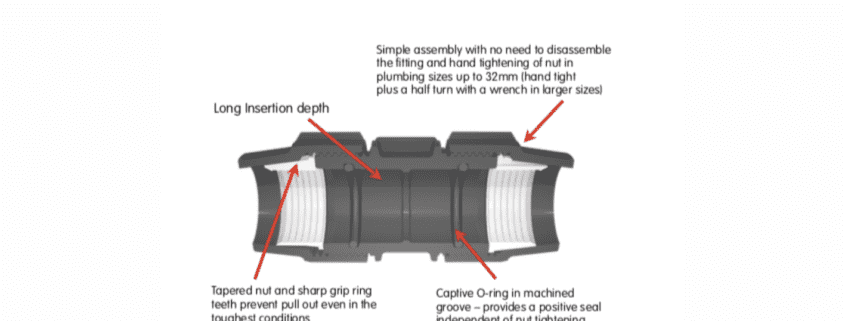

The humble O-ring delivers a reliable seal through compression and that is why PE pipe joiners that seal via O-rings are described as compression fittings.

PLASSON seals due to a simple solution

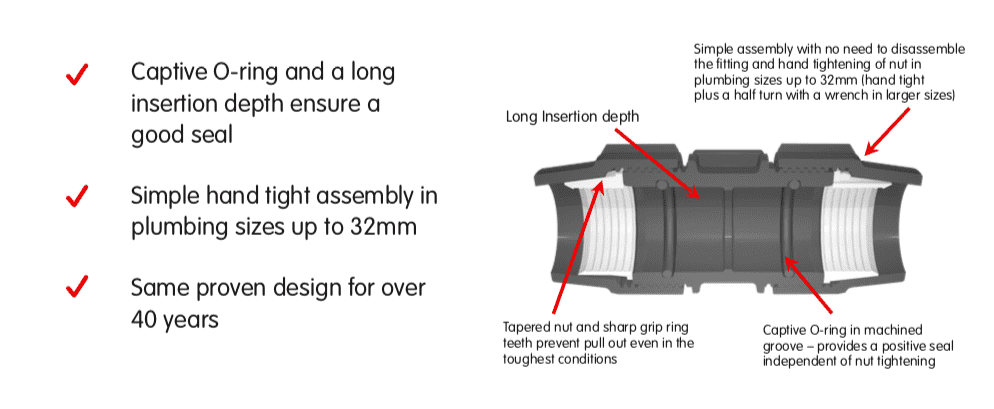

PLASSON took the original O-ring from 1896 and did something simple but clever with it. By placing the O-ring into a special groove machined into the inside of each fitting, the PLASSON O-ring is always in the optimum position for sealing.

This innovative design means the fitting seals water-tight as soon as the pipe passes through the O-ring. With PLASSON compression fittings, you only tighten the nut to prevent the pipe and fitting from moving apart, or blowing out, under pressure. The design also means the O-Ring can’t fall out and be damaged, contaminated or lost during installation.

The O-ring is a donut-shaped ring (technically, a toroid) with a circular cross section made from different elastomers.

PLASSON compression fittings can have Nitrile NBR O-rings or EPDM O-rings, which has a better chemical resistance than NBR, or Vitron seals, which offer better chemical resistance than EPDM.

The name Viton is a trademark and refers to fluorocarbon O-rings, or FKM/FPM for short. This material has an excellent tolerance for high temperatures, resistance to oils, fuels and hydraulic fluids as well as aromatics and solvents.

O-rings seal by mechanical deformation (caused by compression) which creates a barrier to a fluid’s potential leak path between two closely mated surfaces.

Applying fluid pressure pushes the O-ring against the groove wall on the low-pressure side, increasing the sealing force. At higher pressures, the O-ring deforms to a “D” shape, increasing the contact area further.

The range of PLASSON compression fittings includes small 16mm and popular residential plumbing fittings at 20mm, 25mm and 32mm right up to large 63mm couplers for civil water and waste water pipelines.

PLASSON compression fittings are easy to install – just take a look at our install video:

Who doesn’t want simple and cost-effective control of their water… life is complicated enough as it is! That’s why PLASSON developed the

Quick Coupling Valve. This handy device allows pressurized water to be turned off and on with a simple click in key.

Usually installed at ground level, the QCV internal valve is normally closed so water does not leak out. The valve is activated by lifting the flipcap and inserting the “KEY”. On top of the key you can insert a sprinkler or a hose.

QCV’s deliver cost-effective irrigation and stock watering without complicated systems or software.

Click here to watch our simple install video…

Why PE makes sense and cents!

This industry is pumped full of letters and numbers – like SDR11, HDPE, PE100 and PN16. There is handy information in those codes that explains exactly what amazing PE can do. And, when it comes to the different grades of PE, or polyethylene, the magic of what each one delivers is definitely in the detail.

You will find LDPE widely used in plastic packaging or plastic wrap. HDPE is often found in construction and plumbing. And UHMW PE, which is many times stronger than steel, is a high-performance plastic used in bulletproof vests!

The process that makes PE a success was developed in the 1950s by two scientists, Karl Ziegler of Germany and Giulio Natta of Italy. Polyethylene is now one of the most widely produced thermoplastics in the world. It’s light and strong – it’s cheap to transport, easy to handle and safe to store making it a smarter choice than most other materials – especially when it comes to PE pipe.

Drilling down

Polyethylene, like other plastics, starts with the distillation of hydrocarbon fuels into lighter groups called “fractions”. Some can be combined with other catalysts to produce plastics (typically via polymerization or polycondensation).

Low-Density Polyethylene (LDPE) is a very flexible material with unique flow properties that makes it particularly suitable for shopping bags and other plastic film applications. LDPE has high ductility but low tensile strength, which is why it stretches when strained.

Ultrahigh Molecular Weight Polyethylene (UHMW) is an extremely dense version of polyethylene. It is spun into threads with tensile strengths many times greater than steel and used in bulletproof vests and high-performance equipment.

High-Density Polyethylene (HDPE) is a robust, moderately stiff plastic with a highly crystalline structure. It is used to make all types of strong and tough containers. The HDPE used to produce corrosion-free, long-life pipelines for water, waste water and gas is called PE100. PLASSON’s range of poly pipe joiners are designed to easily and securely join PE100 pipelines.

PE is classified as a “thermoplastic” (as opposed to “thermoset”), based on the way the plastic responds to heat.

Thermoplastic vs thermoset

One of the benefits of thermoplastics is they can be heated to their melting point, cooled, and reheated again without degradation. By contrast, thermoset plastics can only be heated once. The first heating causes thermoset materials to set (a bit like a 2-part epoxy), resulting in a chemical change that cannot be reversed. These properties are what makes PE ideal for gas pipelines joined by electrofusion fittings like the PLASSON SmartFuse range.

PE is rugged, flexible, and durable. Both the pipe and PE pipe fittings have outstanding chemical and environmental stress crack resistance. PE pipelines have been successfully used in a wide variety of applications for over 50 years. Add to that strength and corrosion-resistance, and you get a life-span far in advance of other pipe materials.

TAKE A LOOK AT THE INNOVATIVE RANGE OF PLASSON PE PIPE FITTINGS HERE…

HDPE pipe fittings help connect HDPE pipe together. PLASSON fittings can join HDPE pipe in different ways: electrofusion fittings join pipe permanently through fusion; metric compression fittings seal through an internal O-ring being compressed to form a seal between the fitting and the pipe; and BSP threaded fittings join pipe through threaded connections.

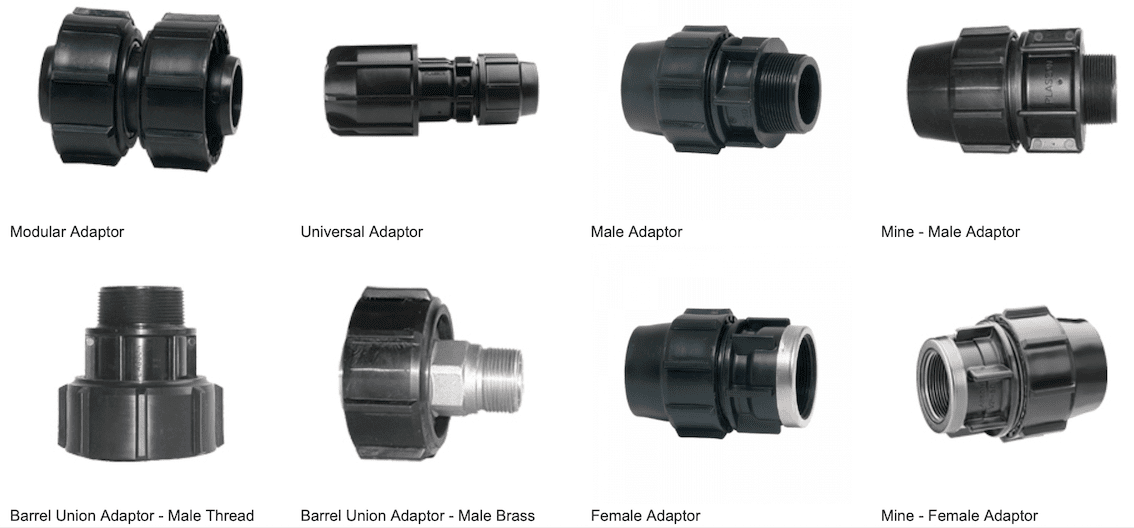

There is a surprisingly vast range of poly pipe compression fittings. Even the most familiar options, like couplers, tees and elbows, have a range of reducing and connection options that can take some time to understand.

While pipe fittings or connectors attach one pipe to another in order to lengthen the run or change the flow direction in a plumbing system, there are also lots of clever fittings that do so much more to make plumbing life easier. They can combine, divert or reduce the flow of the water supply. They can monitor flow or stop it, reduce pressure and provide outlets for sampling.

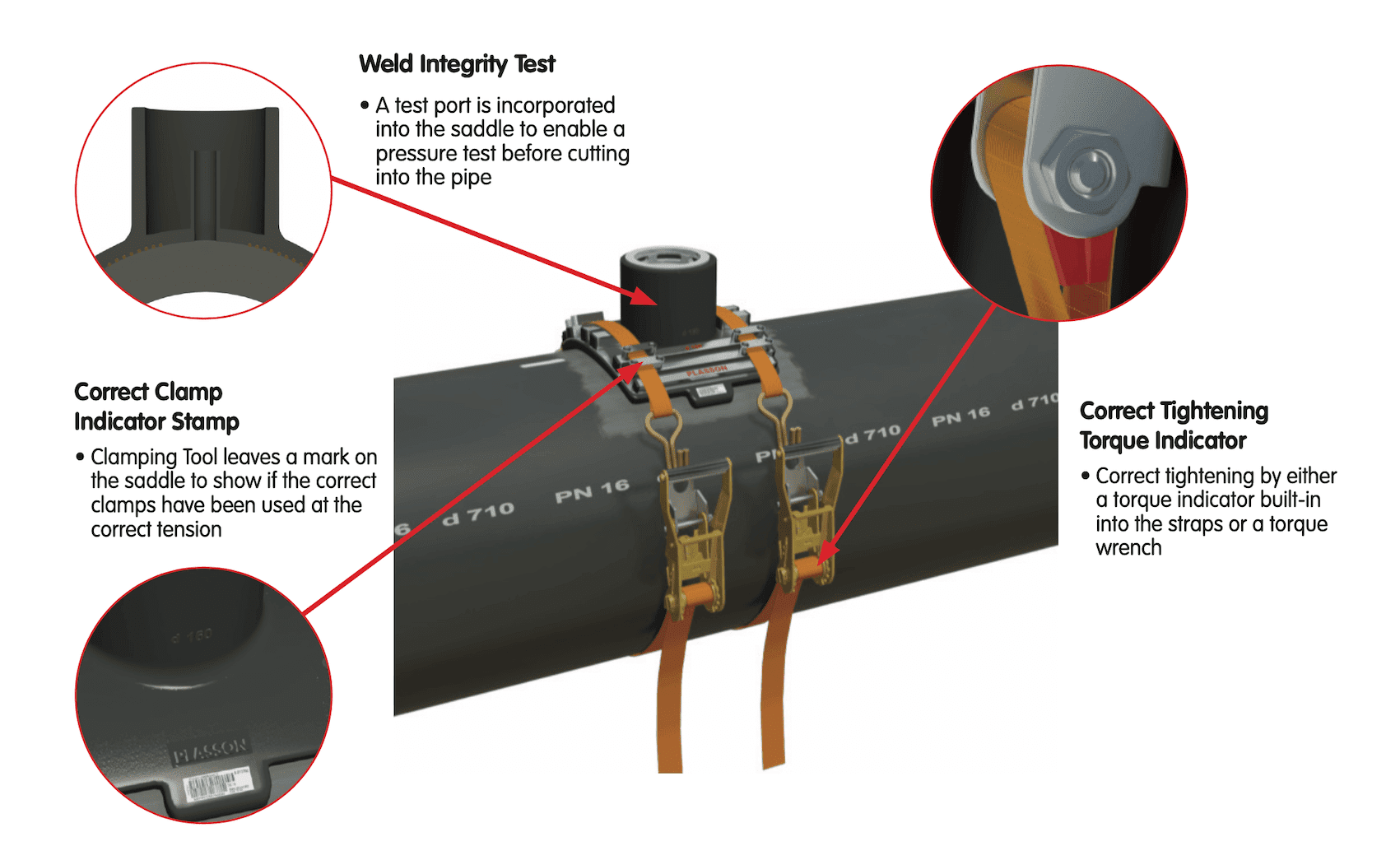

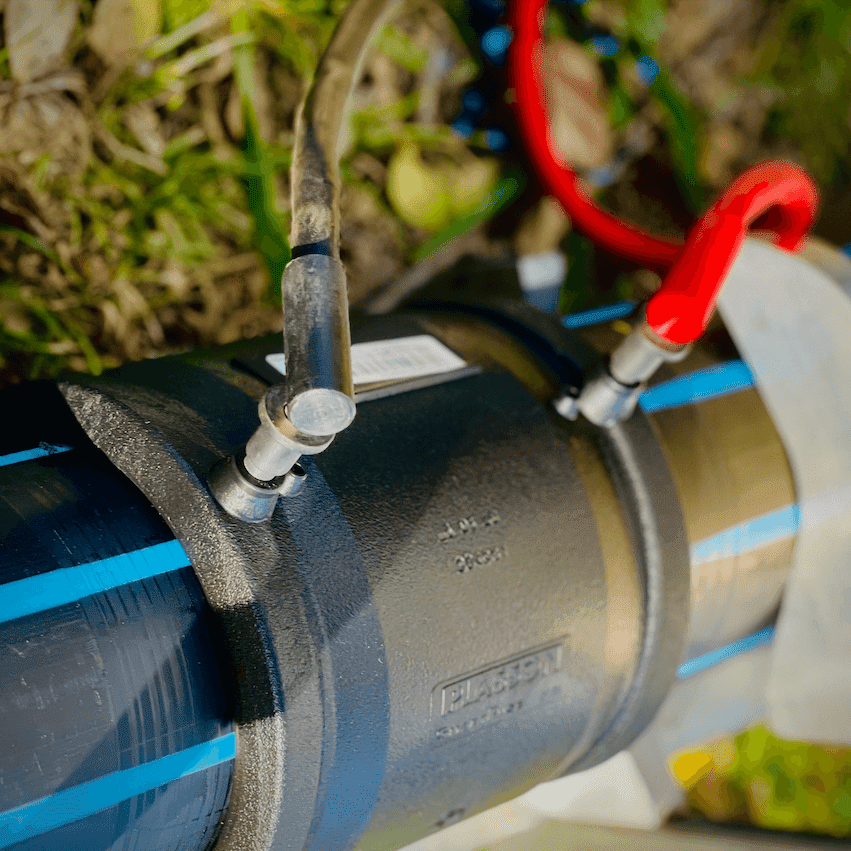

PLASSON compression fittings have a number of unique features that help deliver leak-free connections and reliable, long-life PE pipelines.

Compression fittings come in a range of standard sizes. PLASSON compression fittings start small for domestic plumbing at 16mm, 20mm, 25mm and 32mm and continue up to civil and industrial sizes like 40mm, 50mm, 63mm and right up there to above 1000mm.

All PLASSON compression fittings seal the instant they go on the pipe due to an innovative O-ring design. The O-ring is held captive in the body of the fitting in a specially designed groove. This simple piece of engineering means the O-Ring can’t fall out, get contaminated or become easily damaged like other compression fittings.

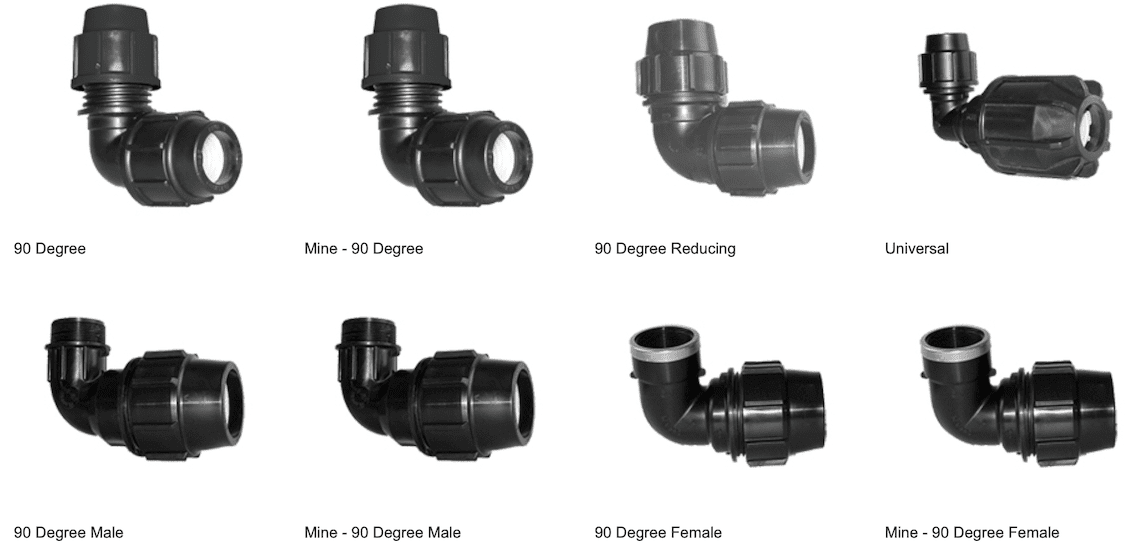

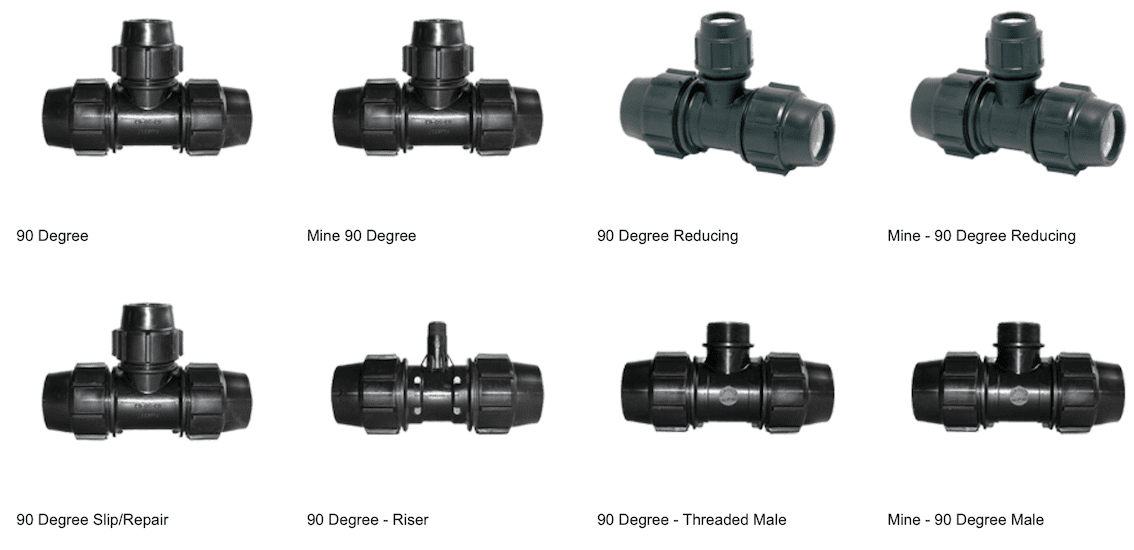

While most have openings of the same size on each end, some fittings are designed with different-sized openings and serve as the transition from one size pipe to another. The following briefly explains some of the different PLASSON fittings, where and how they are used.

To see the full range of PLASSON metric compression poly pipe fittings click here…

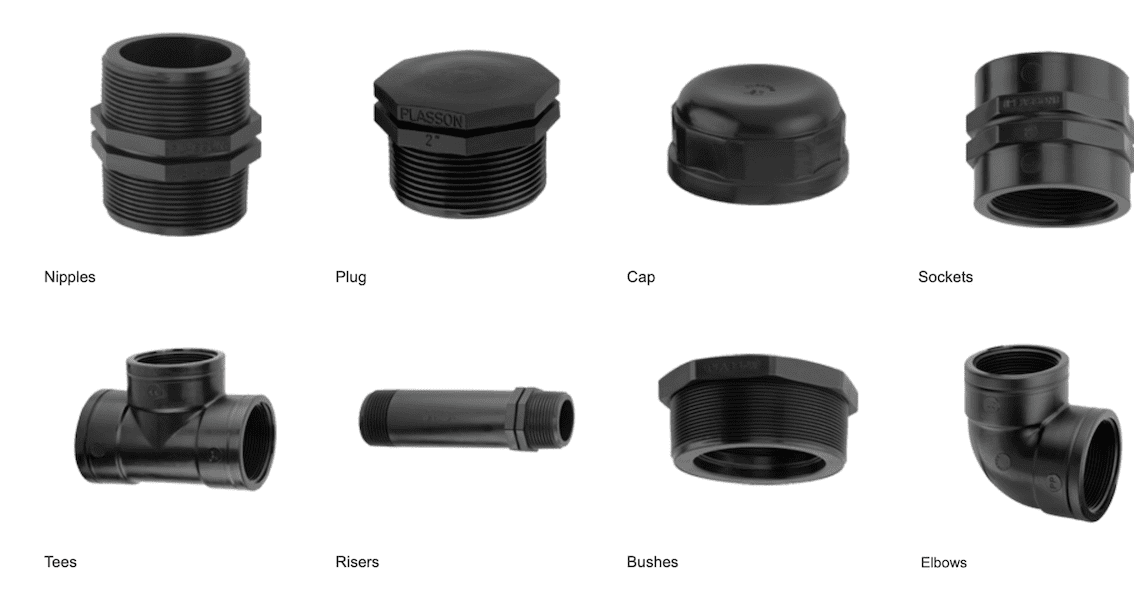

Tee Fittings & Wye Fittings

Tees and wyes are used to connect three pieces of pipe. Tees can have one inlet and two outlets at 90-degree angles in the shape of a “T” and are used to split a supply line, or they can combine two lines into one outlet. You often see tee fittings connected to potable water supply lines. A wye is shaped like a “Y” with the two inlets coming together at roughly 45-degrees into a single outlet in drain applications.

Elbow Fittings

Elbows change the direction of flow between two pipes. Common elbows have 90-, 60-, 45- and 22 ½-degree bends and are used to make a turn. They can be joined together to move around obstructions in a pipe run.

Coupling & Adapter Fittings

Pipe couplers slip over the outside of two pipes to connect them. A coupling can be a reducer, or reducing coupling, meaning they reduce flow by joining a larger pipe to a smaller size. Adapters are used when connecting two pipes of different types. For example, an adapter could be fitted on the end of a plain pipe to allow a threaded connection at the other side of the adapter, or to connect poly pipe with another pipe material, like copper.

Bushing Fittings

Bushings, sometimes called reducer bushings, are used for connecting two pipes of different sizes. The larger diameter of the bushing fits inside of the larger pipe. The smaller pipe is then inserted into the smaller end of the bushing.

Flange Fittings

A flange is a flat, round fitting that creates a tight seal with bolts or clamps. They are used when pipes pass through walls, ceilings and floors. They are also used in electrofusion installations to connect valves to main lines.

Cap Fittings

A cap fits over the end of a pipe to stop the flow of water or gas. These fittings can be used for the permanent termination point of a pipe or used temporarily to cut off supply during a plumbing or pipeline project.

Plug Fittings

Plugs used at the end of a pipe to seal the opening, similar to a cap. The difference is that a plug fits into the threaded pipe opening to make the seal while caps fit over the opening. They are commonly found at cleanout locations for sewer systems.

Nipple Fittings

Nipples are short sections of pipe that are male-threaded at each end and used for connecting two female-threaded pipe ends or fittings.

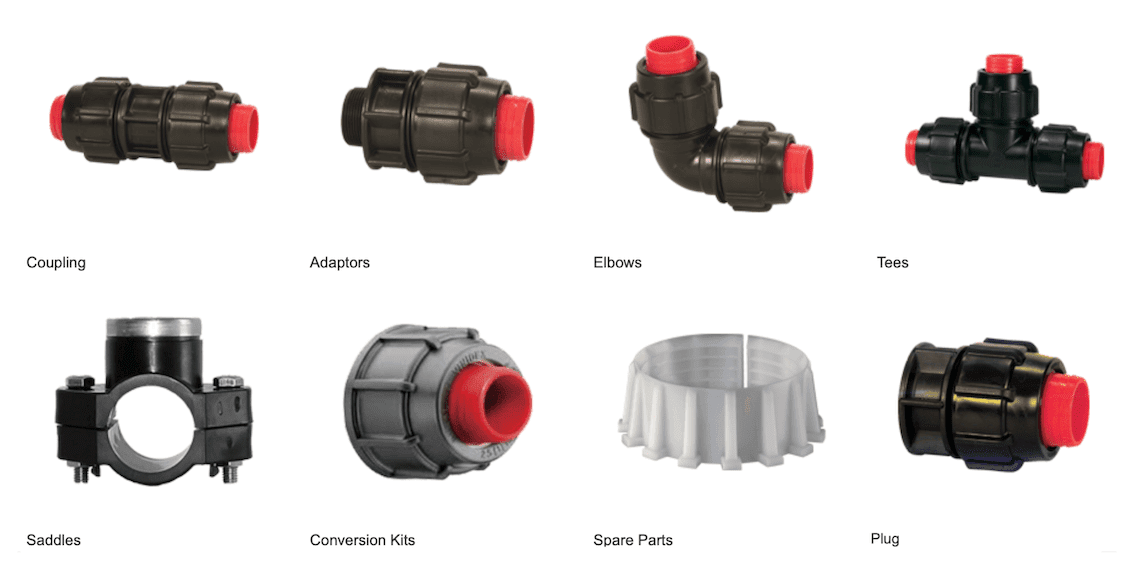

Ag Pipe Fittings

Agricultural pipe is widely used for stock watering, water mains, irrigation systems and bore water reticulation. PLASSON rural couplings and clamp saddles are specially designed to connect imperial-size polyethylene pipes from ¾” to 2″. The range is compatible with PELD, PEHD, PE40, PE80 and PE100 pipes complying with AS/NZS 4130. PLASSON’s special red barbed inserts fit a range of pipe dimensions so that ag pipe can be easily connected without the need for any tools.

The PLASSON range includes solutions for most plumbing situations. You can take a look at the catalogue for the full range here….

ABOUT US

Over the last 60 years PLASSON has grown into a global team of over 2,000 talented experts.

We have built a reputation for product, service and support through hard work, innovation and passion.

PLASSON is engineered to deliver.

WAREHOUSES

Melbourne: 7.30am-4pm

25 Business Park Drive

Ravenhall VIC 3023

Brisbane: 7am-4pm

49 Distribution Street

Larapinta QLD 4110

Perth: 7am-3.30pm

8 Tacoma Circuit

Canning Vale WA 6155

CONTACT DETAILS

All Queries

1300 752 776

Sales Email

[email protected]

Head Office

61 Dunning Avenue

Rosebery NSW 2018

GOT QUESTIONS?

Whether you need to know about installation, application, size range or product codes, our team are here to help on 1300 752 776

Or take a look at PLASSON FAQ’S