When it comes to water, wastewater and gas pipelines, poly pipe (or polyethyene/PE as it is also known) is hard to beat. The flexible nature of polyethylene pipe allows it to be used in colder climates – where it will not crack – and in situations where rigid pipe would require multiple elbows to make complex turns.

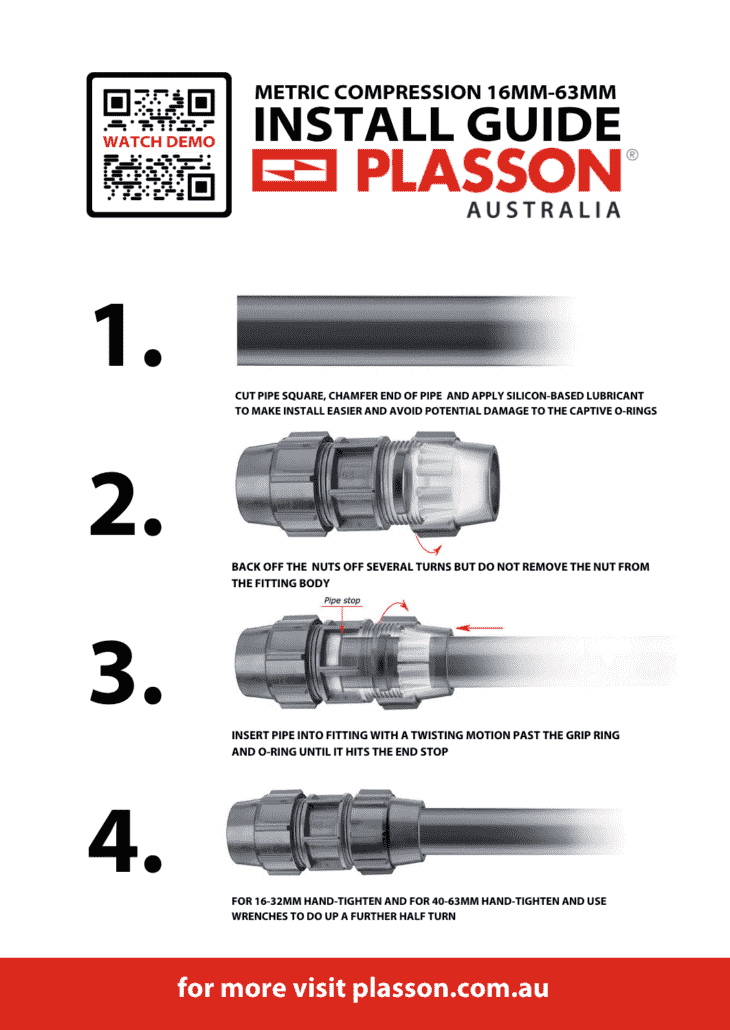

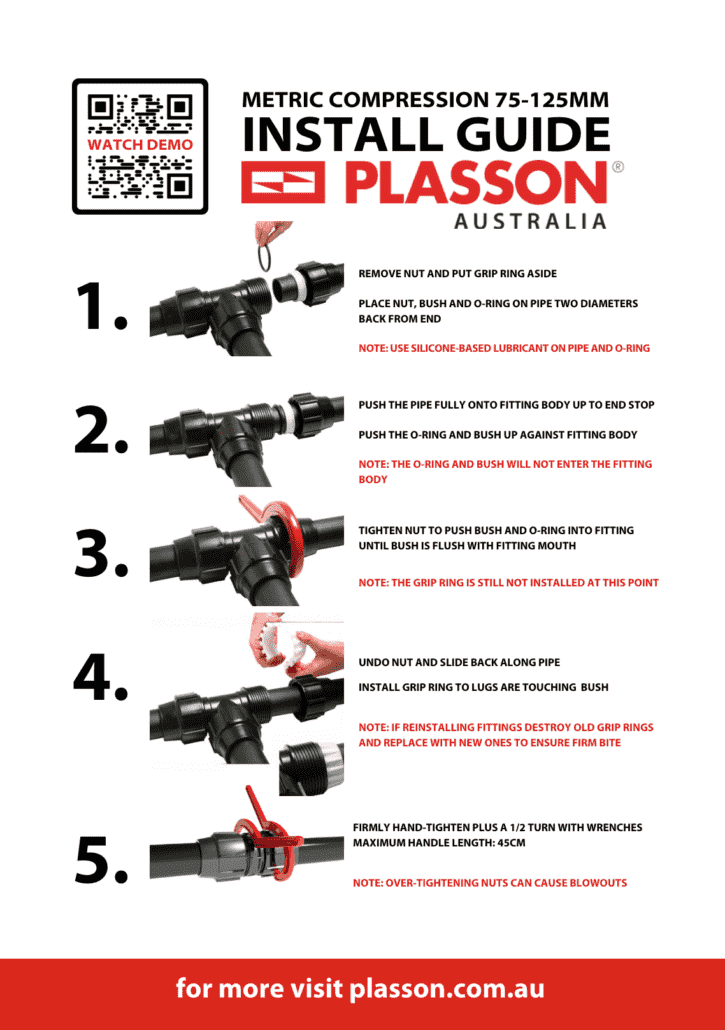

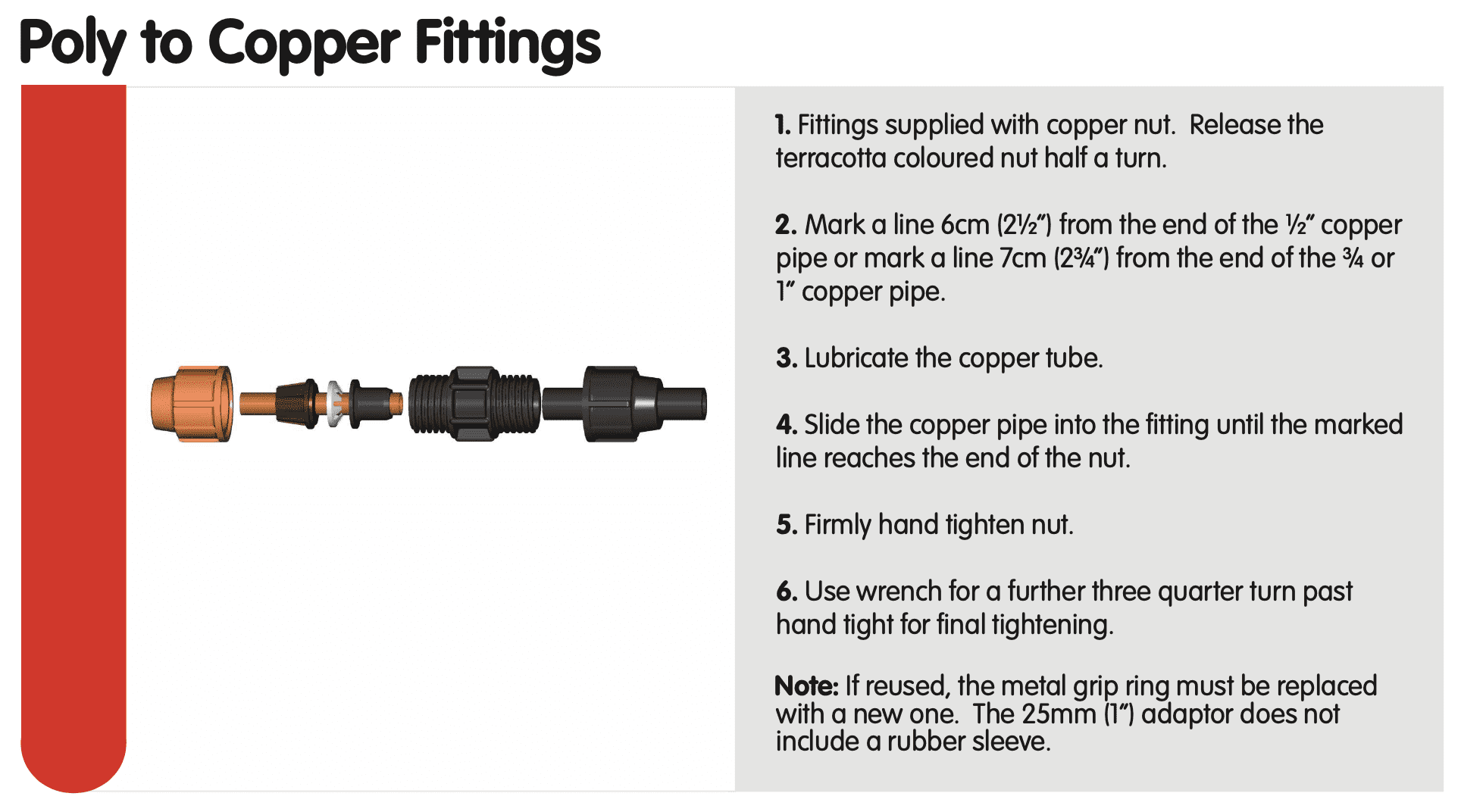

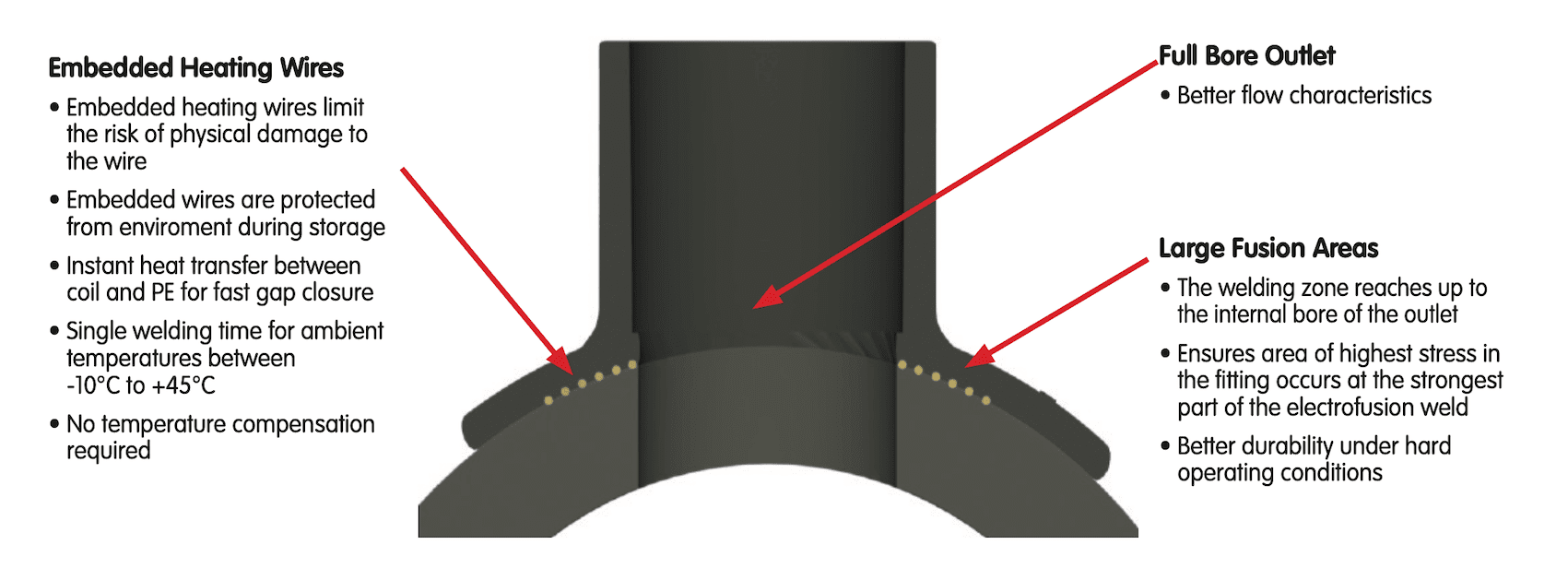

Unlike other plastic piping, poly pipe connections do not use glue to solvent weld pieces together. Instead, specially designed fittings seal poly connections using compression – this is why they are sometimes known as compression fittings.

PLASSON has engineered a range of simple yet smart compression fittings to make joining poly pipe easy and reliable. All PLASSON poly pipe joiners feature a unique O-ring design that means the fitting will seal the moment it goes on the pipe – tightening the nuts on PLASSON compression fittings is only neccesary to hold the pipe in place and prevent blow outs.

This innovative design feature means PLASSON compression fittings are easy to install with a minimum of tools.

All PLASSON poly pipe joiners are corrosion-resistant and made of UV stablilised material for a long service life.

INSTALL GUIDE FOR PLASSON PLUMBING FITTINGS

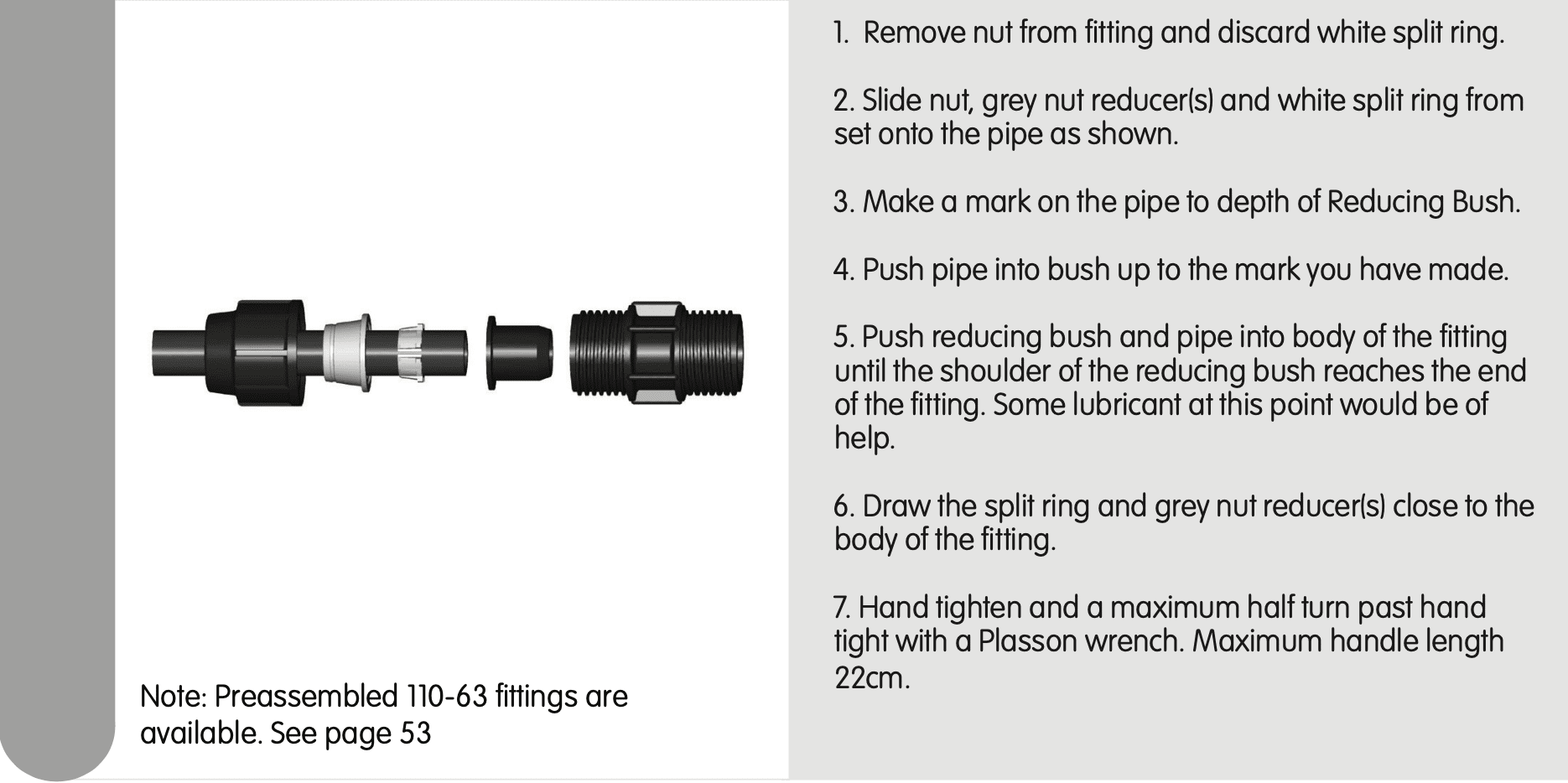

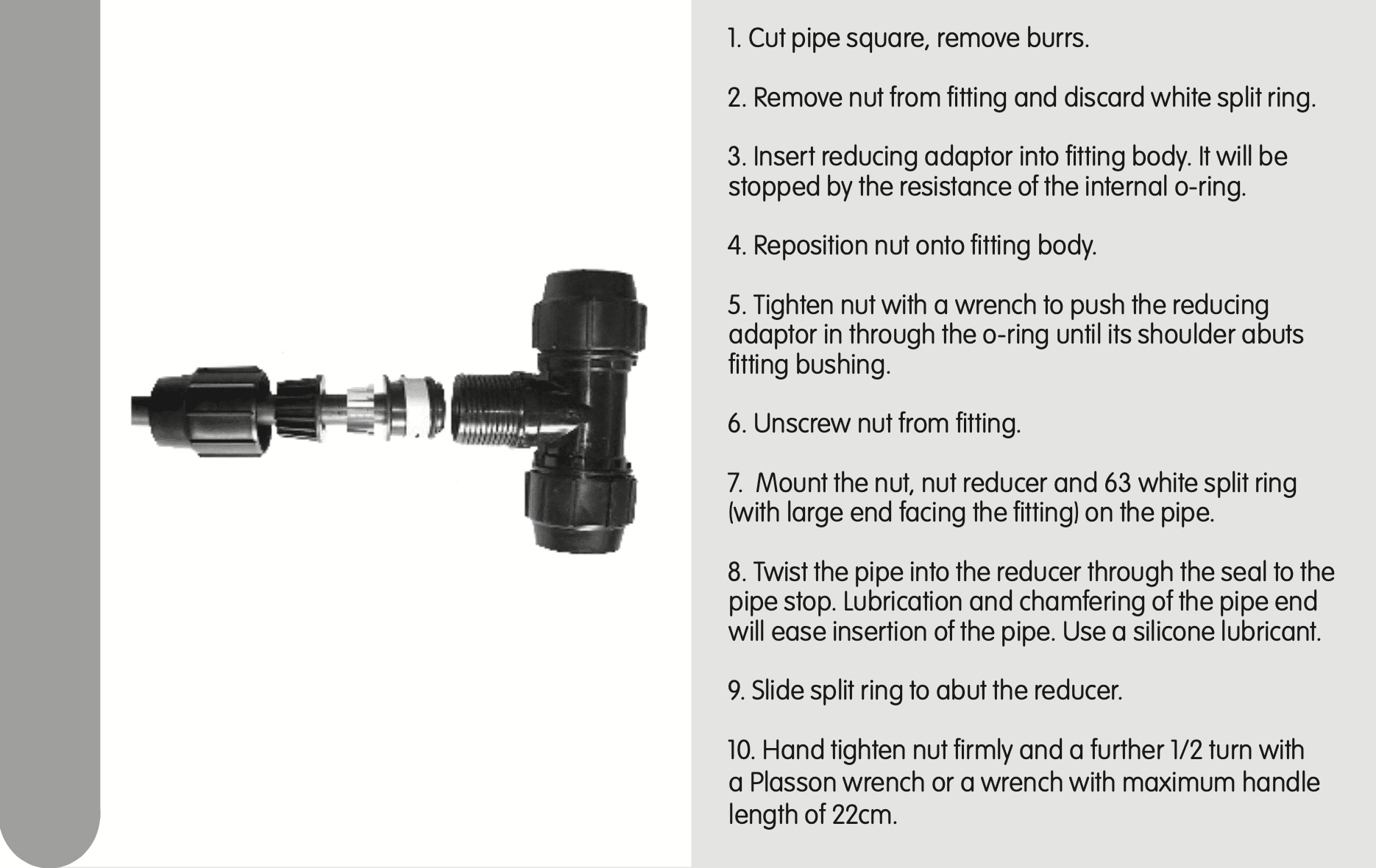

HOW TO JOIN POLY PIPE OF DIFFERENT SIZES

PLASSON REDUCING FITTINGS CONNECT PIPE OF DIFFERENT DIAMETERS

Leave a Reply

Want to join the discussion?Feel free to contribute!