No-one wants to re-do welds so the best way to save time, money and hassles is to ensure each and every weld is done according to best practice. The key to good electrofusion welding is contained in the POP001 guidelines for electrofusion installation.

POP001 was put together by PIPA, the Plastics Industry Pipe Association of Australia to detail the best practice processes and parameters for electrofusion welding. Following these steps will help ensure quality, long-lasting and reliable pipe connections, helping you be a better installer and achieve more reliable, leak-free EF welds.

This quick install video shows how the steps outlined in POP001 apply in the field.

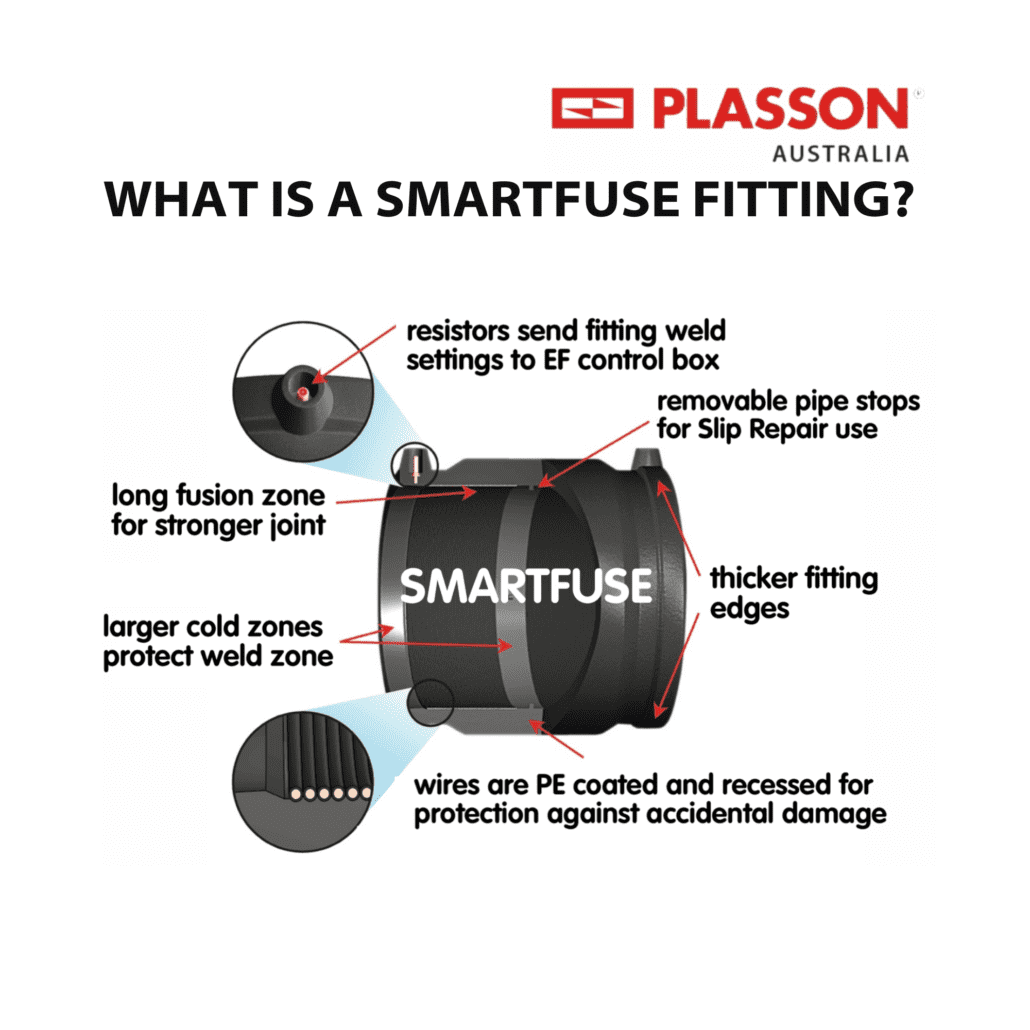

PLASSON has developed the SmartFuse system to help make electrofusion welding simplier. All SmartFuse fittings have built-in resistors that automatically load the correct weld parameters for the fitting into PLASSON SmartFuse electrofusion weld machines.

Welding is made even easier thanks to the SmartFuse app. It not only guides and prompts installers to complete all of the best practice steps in POP001, the SmartFuse app records this information and the weld record either on USB or in the cloud.

It is important to know and understand all the steps outlined in POP 001 as omitting steps or failing to complete processes adequately can undermine weld quality and lead to failed pipelines.

The processes outlined in POP001 are known as best-practice. It is crucial to always follow best-practice as failure to do so can open operators up to claims of negligence and compromise insurance cover.